We at Setco Automotive place our customer's need for exceptional service and responsiveness at the top of our service agenda. Through an ever-expanding network, we assist and provide support to our customers with a focus on total customer satisfaction.

We conduct training programs for vehicle manufacturers, their dealers and distributors, on the mechanics of our clutch settings and maintenance.

We recently initiated Service Meets to garner critical customer feedback, assimilate best service practices, and stay updated on current market trends in the field.

Proper training of drivers and mechanics can go a long way towards extending clutch life. Anyone who drives the truck, whether on or off highway, should be taught how to operate the vehicle properly.

The most critical points to cover in driver training programs are:

The most important points that can affect clutch’s performance are:

Cause – Driver foot riding on Clutch pedal. Starting the vehicle in 2nd or higher gear.

Repaired Clutch DiscOne rivet head is on the flywheel side and the other on the pressure plate side. This is not as per manufacturers specifications.

Uneven Contact of Clutch DiscIt is a normal phenomenon that the outer area (green) of the clutch disc will wear more than the inner area (red).

Damage/Rubbing Mark on End of Release Bearing SleeveClutch adjusted incorrectly. This allows the release bearing assembly to make contact with the hub.

Sleeve Bushing DislodgedClutch adjusted late or incorrectly.

Retractor Spring BrokenImproper tightening of eye-bolt and adjusting nut while repairing.

Worn Pressure PlateInduced clutch slip. Driver foot riding on clutch pedal. Starting the vehicle in 2nd or higher gear. Heat damage to all mating surfaces. Incorrect clutch/cylinder setting.

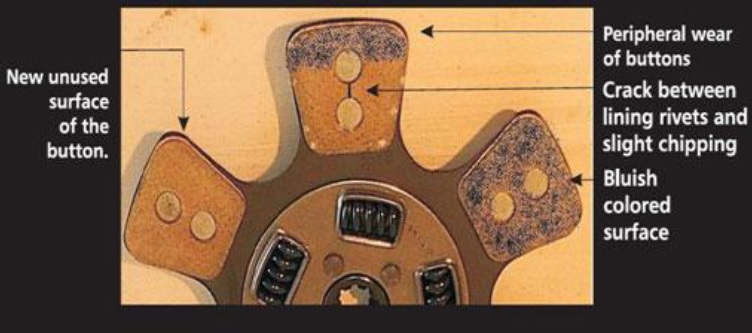

Facing Worn Out up to Rivet HeadThe life of the clutch is over.

Rubbing Mark on HubRelease bearing sleeve in contact with the hub since clutch was adjusted late or incorrectly.

Clutch Disc BentMishandling of the disc while removing it from the vehicle.

Damaged Wear PadsMishandling of the disc while removing it from the vehicle. Mishandling of the product.

Retractor Spring BrokenPressure spring missing while repairing or clutch has been opened from the vehicle without putting hold down bolts, forcing the retractor spring to come in between the lever and spider.

Worn Collector RingDriver foot riding on clutch pedal. Clutch actuation system not set up correctly. Release bearing operating under constant load.

Thermal Cracks on Pressure PlateIn normal clutch operation, hot spots will appear. Continuous partial engagement results in slippage, causing excessive heat, which is abuse.

Checks to be Done