Clutch Facing Fully Burnt

- Cause – Driver foot riding on Clutch pedal.

- Starting the vehicle in 2nd or higher gear.

Repaired Clutch Disc

One rivet head is on the flywheel side and the other on the pressure plate side. This is not as per manufacturers specifications.

Uneven Contact of Clutch Disc

It is a normal phenomena that outer area – green of clutch disc will wear more than inner area – red.

Damage/Rubbing Mark on End of Release Bearing Sleeve

Clutch adjusted incorrectly. This allows the release bearing assembly to make contact with the hub.

Sleeve Bushing Dislodged

Clutch adjusted later or incorrectly.

Retractor Spring Broken

Improper tightening of eye-bolt and adjusting nut while repairing.

Worn Pressure Plate

- Induced clutch slip. Driver foot riding on clutch pedal.

- Starting vehicle in 2nd or higher gear.

- Heat damage to all mating surfaces.

- Incorrect clutch / cylinder setting.

Facing Worn Out up to Rivet Head

The life of clutch is over.

Rubbing Mark on Hub

Release bearing sleeve in contact with the hub since clutch adjusted late or incorrectly.

Clutch Disc Bent

Mishandling of disc while removing from the vehicle.

Damaged Wear Pads

Mishandling of disc while removing from the vehicle.

Damaged Wear Pads

Mis-handling of the product.

Retractor Spring Broken

Pressure spring missing while repairing or clutch has been opened from vehicle without putting hold down bolts forcing retractor spring to come in between lever and spider.

Worn Collector Ring

- Driver foot riding on clutch pedal.

- Clutch actuation system not set up correctly.

- Release bearing operating under constant load.

Thermal cracks on pressure plate

- In normal clutch operation hot spot will appear.

- Continuous partial engagement results in slippage causing excessive heat which is abuse.

Checks to be done

- Check for smooth engagement and smooth return of clutch pedal (Ensure the presence of pedal return spring, ensure that pedal linkages and bushes are greased).

- Check pedal free play (Should be 5 to 10 mm. If not adjust pedal linkages to get required play).

- Check full travel of the pedal to the bottom of the floor (There should not be any obstructions).

- Start engine and check at what point of pedal travel the clutch is released and engaged (Clutch engagement & dis engagement should take place between ½ to 2/3rd of pedal travel.

- Check for the movement of master and slave cylinder (Movement should not be sticky).

- Check is bleeding of hydraulic cylinders is done (Bleed the system of pedal is spongy).

- Check for the stroke of slave cylinder by depressing clutch pedal fully (Should be min 18 mm at the slave cylinder rod which can be checked with a scale).

- Make sure that the clutch setting has been done at prescribed kms (gap between gearbox cover and release bearing assembly should be 19 ~ 22 mm. Adjust to 19.5 mm and check after every 9000 kms).

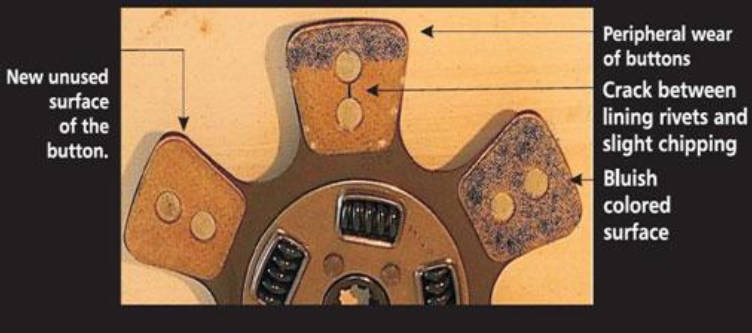

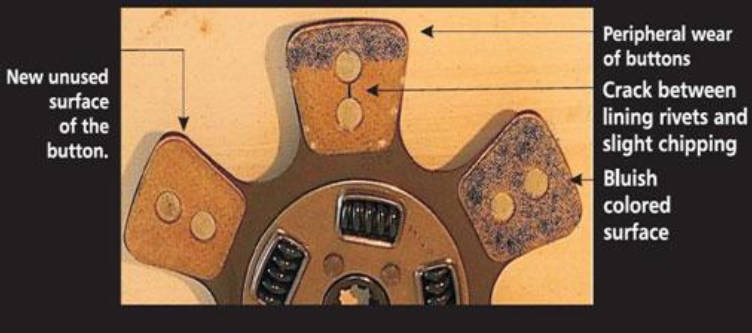

Ok clutch disc

- Loose rotating damper springs.

- Glazed bluish colored lining surface.

- Uneven contact.

- Hairline crack between ceramic button.